The Pareto principle, also known as the 80/20 rule, holds significant weight in the manufacturing industry. It suggests that roughly 80% of the results (outputs, benefits) come from 20% of the causes (inputs, efforts). By strategically applying the Pareto principle, manufacturers can optimize their resource allocation to reduce downtime, eliminate scrap and improve overall equipment effectiveness (OEE), and unlock hidden capacity to generate revenue opportunities.

Production monitoring systems are a great way to gain valuable real-time visibility into operations without getting bogged down in complex setups or hefty costs. One of the toughest questions when looking at the factory model as a whole can be: where do I start?

Here are some specific ways the Pareto principle can be applied in manufacturing production processes:

- 80% of your defects might be caused by 20% of the machines or processes. Focus on identifying and improving these critical areas to significantly reduce defects and waste.

- 80% of your downtime might be caused by 20% of downtime reasons. Implement proactive maintenance measures for these critical machines to minimize downtime and ensure smooth production flow.

The Power of Context When Examining Defect Causes in Manufacturing Analytics

One of Mingo Smart Factory’s customers realized that a specific machine was not going down sporadically. The manufacturer realized that the same machine went down whenever the machine was reset to run a specific part and then hit a temperature threshold before defects started to emerge. The operators were able to better track temperature variances so that the output quality became more consistent.

Context is key when evaluating real time data from the factory floor. Mobile alerts helped one of Mingo Smart Factory’s customers know when a machine that he had marked as down for maintenance on Friday, was accidentally turned on by the weekend crew. One phone call prevents thousands of dollars of defective product from becoming scrap.

Read more: Oral BioTech increased OEE 20% and reduced scrap to nearly zero.

Identifying Significant Downtime Causes

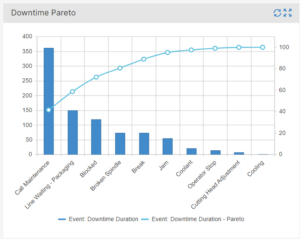

Let’s take a look at this sample Downtime Reason chart for a food manufacturing line that makes sandwiches. The 3 categories that have the highest counts for downtime are Call Maintenance, Blocked, and Jam. However, clearing the Jam takes only an average of 5.43 minutes while Maintenance calls take more than 30 minutes. Sticky indeed.

To get a better idea of what is ACTUALLY contributing the most to downtime, we can take the data table and insert it into a Pareto Chart. The Downtime Pareto chart reveals that 80% of downtime is from four categories:

- Maintenance

- Packaging

- Blockage

- Broken Spindle

Focusing on what is causing maintenance issues will address 40% of the downtime issues with one initiative. Integrating production monitoring software with a maintenance program like Fiix can alert operators when preventative maintenance is needed. H&T Waterbury was able to do just that to sync vibration, temperature and production data to know when a machine was about to need maintenance.

Data Driven Decision Making

Find inefficiencies in a few clicks and optimize your factory with just 5 minutes of monitoring per day with Mingo Smart Factory. Continuous improvement is a journey. You need software that can grow with you.

Convincing your managing team to invest time, energy and funds into a new way of reporting can be challenging. The status quo can be an easy place to stagnate. Metrics are the key to success.

Here are some tips for using the 80/20 rule effectively:

- Identify the 20% that matters most. This may require some analysis and experimentation.

- Focus your time and resources on the 20%. Don’t waste time on things that are not going to give you a big return.

- Don’t neglect the 80%. The 80% may not be as important as the 20%, but it can still be important. Just make sure you’re not spending too much time on it.

- Be flexible. The 80/20 rule is a guideline, not a rule. There will be times when it doesn’t apply perfectly.

Mingo Smart Factory is the easiest plug-and-play production monitoring solution for manufacturers. Hardware and software components arrive already configured 80% out of the box. Yes – we use the Pareto Principle in our deployment as well – to help manufacturers like you get started as fast as possible. Start measuring data and identifying inefficiencies in days, not months.

Start simple, think big, move fast. By choosing an easy-to-implement production monitoring system and using it effectively, you can gain valuable insights that will help improve efficiency, reduce costs, and boost your bottom line.