“It’s really a production and process tool. It works with maintenance and scheduling, too. All activities plus reporting are in Mingo – downtime, planned changeovers, PM maintenance, unplanned activities, yield calculations, overall OEE, cycle times, all of it.

We send reports to corporate using Mingo.

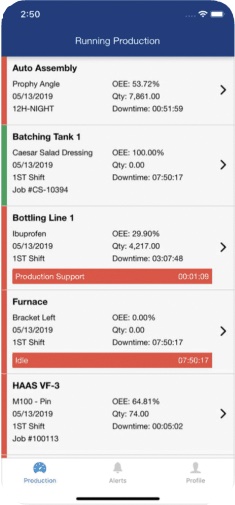

There’s an application on the phone that is very beneficial. If I’m not here or it’s the weekend, it provides a good overview of what’s going on.

Really, we knew we had a lot of errors. Mingo confirmed this. For us, it was about how poorly we were reporting data. It just gives me confidence and confirms the problems we know we need to address. The auditable piece of it tells me I’m going after the right things.

For example, we run so many different products. You can only imagine if you’re supposed to produce 20 products, and you thought you did, but you only produced 18. At that point, it’s too late to make the other 2 because you’re on to something else by then. It leads to disappointment somewhere.

Those kinds of issues are more profound than a little extra downtime. We focus on utilization and efficiencies every day, but in the end, if I’m not making the right amount of products that I’m supposed to, it almost doesn’t matter how good I’m producing.

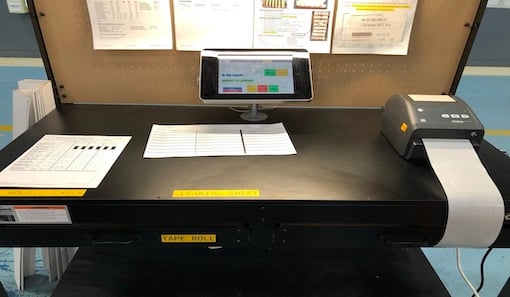

We use [Mingo] in a lot of ways. We’re continually evolving in how we use it. I would never have foreseen some of the areas we’ve gone into with Mingo. I wouldn’t have predicted labeling or box-counting. I like that we continue to evolve with the product.

As everyone in the facility becomes more of a user, that opens up more opportunities for what they’re going to do with the product.

I like that each person can get the pieces out that they need to see. The maintenance manager has parts he wants to see. My process manager has parts he wants to see. I look at things from a bigger picture. But, at the same time, it’s all the same data that gets compiled in a way that is more relevant to that particular person.”