The hard part of job shops is that everything is different, every single day. A job shop can be medium to low volume, but medium to high mix, creating an environment of constant change. Some job shops do produce thousands of the same things, but a lot of job shops are totally custom and everything is engineered to order.

There are unique requirements for a job shop. Each machine, each person, each work center, each cell could be doing something different every day, which makes planning for that really, really difficult. It is much easier to schedule, understand capacity, order products, do quotes, develop cost projections, all of those things you need to run a factory when you’re making the same thing every single day. But, if every day is different and every time you make something, it’s different, how do you plan and predict? And, what metrics do you track to accommodate for the high variability in a job shop?

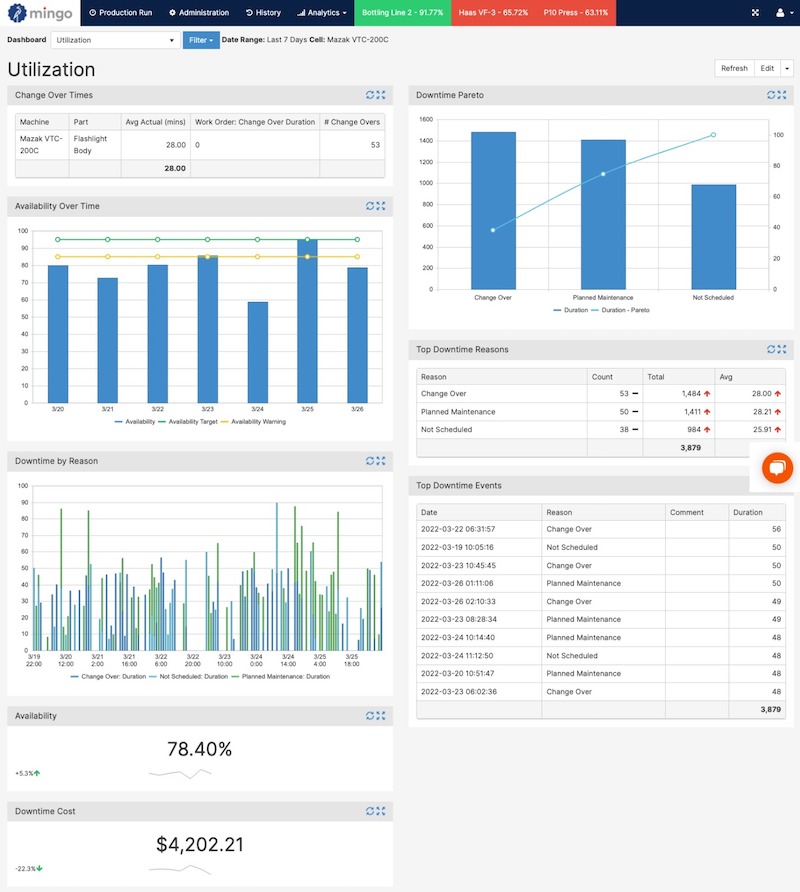

Performance metrics are not the key metrics in a job shop. The plant is not asking, “How many parts were produced on a machine?” But, instead, it’s the changeover times and run times that matter most to the plant operations team. They’re asking:

- “What’s an estimate for how long it takes to set up a machine and changeover from one job to another?”

- “How long should a job take to run? ”

- “Is the job close to that time?”

These are all local optimization numbers. “Is this machine or this operation running the way it should?” And, when you have those numbers, you can begin to look at the more holistic view of the plant by asking:

- “How much capacity do we actually have?

- “If we got a rush job today, where could we actually fit it in?”

So, unlike a more traditional manufacturing environment, performance doesn’t matter nearly as much as the metrics needed to understand changeover and run time. Also while on-time delivery is something that matters to any manufacturer, a job shop places greater importance on the need to track, not only on-time delivery to the external customer, but on-time delivery to the internal customer. Which basically means that from one operation to another, what does that look like and how is it tracked. “So, if we’re supposed to make these parts today and finish them today, did we do that? Yes or no? Why not?”

Let’s not forget about quality, either. In a factory that produces the same product every single day, quality is easily automated. In that highly automated, high volume, repetitive company, you have most of those check processes built into the equipment already. But, in a job shop, measuring quality is typically a manual process. Sometimes, a job shop has tooling and machines that will measure and check parts, but more often than not, the process of monitoring quality falls to job packets or job travelers and humans.

Because everything is different every time, these job packets or job travelers “travel” around the shop for detailing and verifying each step in the production process. The problem with this is the fact that these travelers are paper that can get lost, be torn, spilled on, etc.

This is where job shop software can provide immense benefit in eliminating manual processes, providing visibility, and providing simple scheduling methods.