Manufacturing businesses need software to help them understand what’s happening on the floor and make data-driven decisions that will ultimately help on-time delivery rates, increase customer satisfaction, and grow revenue.

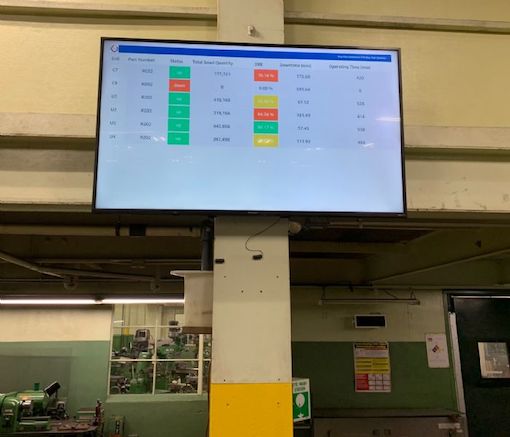

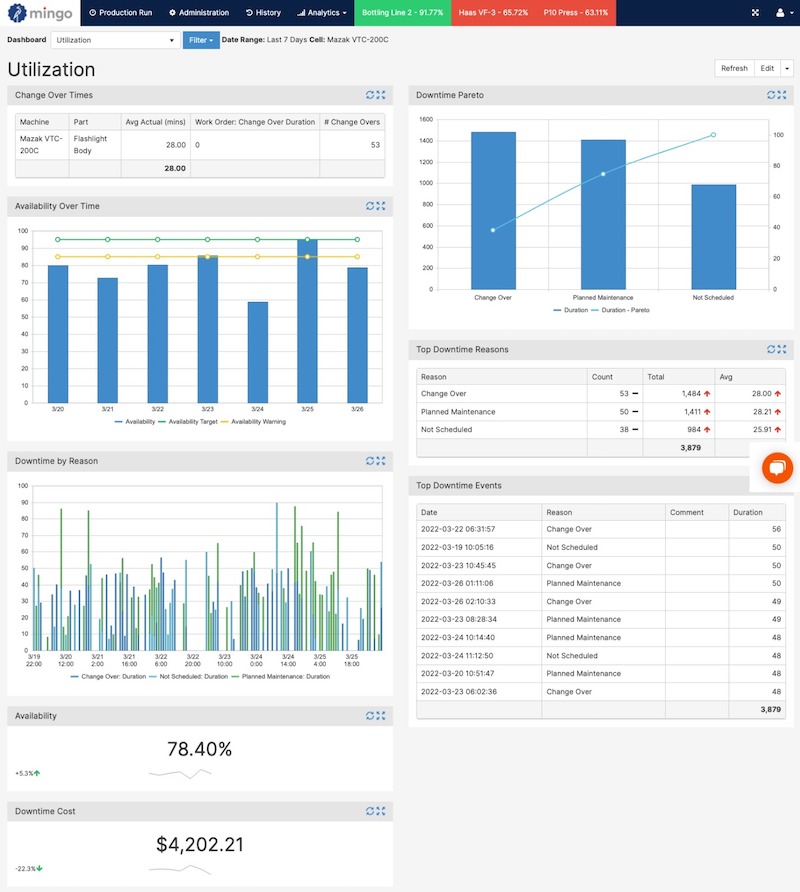

Eliminate Manual Reporting: Specifically, manufacturers will gain the ability to eliminate manual reporting by automating data collection, replacing pen and paper and Excel with real-time dashboards, and receive end-of-shift, end-of-day, or end-of-week reports. No more waiting for someone to collect, report, and send the data, sometimes days later. Now, manufacturers can get insight into production in time to correct any problems that arise.

Know Where You Stand: Traditional planning in an ERP is too rigid, and using Excel is mistake-prone and tedious. With manufacturing productivity software, manufacturers get flexible production scheduling that enables decision-making on the fly. Make decisions based on labor or customer demands to meet goals and get products out the door.

Increase Capacity: Fabricated metal and metal stamping software give manufacturers the ability to find all of the inefficiencies that cause problems and eliminate them. This leads to increased capacity and being able to produce more with the same amount of resources. Manufacturers will see the capacity to produce quicker and increased profitability.

Achieve Quality Standards: Quality is a crucial metric in the metal forming industry. It’s critical to track and measure quality at all times, yet many manufacturers find this difficult to do without the right software in place. With our software, you can understand the quality of a part from data that is automatically collected, eliminating the need for manual reporting. The data provides insights into problems that are occurring, ultimately helping you improve quality.