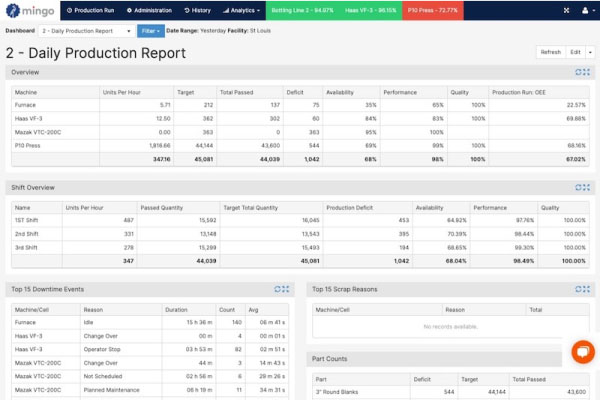

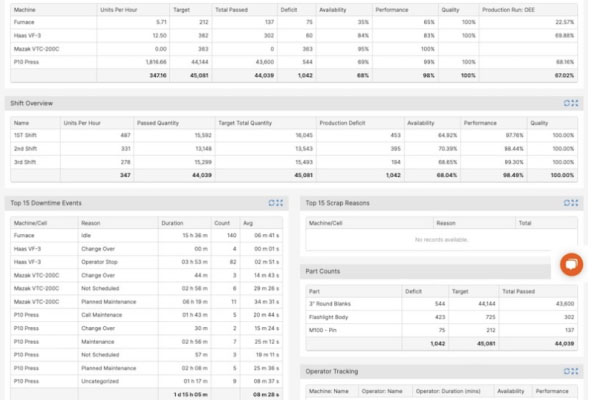

Yes, you can escalate alerts based on the importance and severity of the problem. This means that you can notify key people and ensure that critical issues are not missed. With Mingo Smart Factory, you can see the impact of the problem on productivity throughout the plant and make evidence-based corrective decisions. The benefits of using Mingo Smart Factory for capacity management include real-time visibility into production performance, improved decision-making, reduced lead time, and increased efficiency and productivity. Mingo Smart Factory also supports continuous improvement by providing data-driven insights into production processes and employee performance.