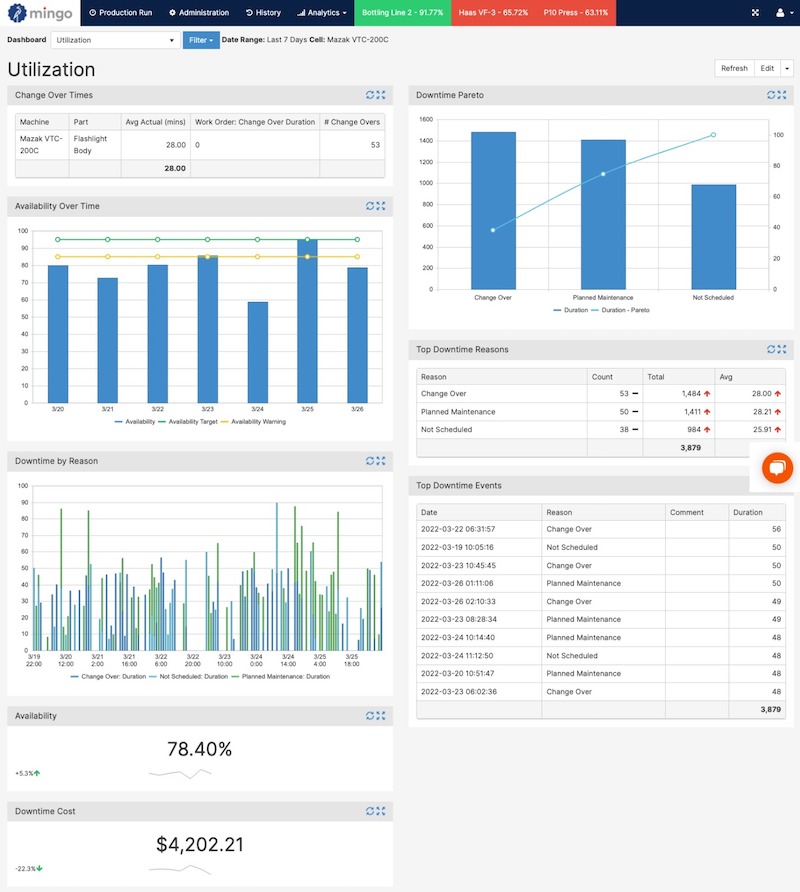

Implementing real-time manufacturing productivity software on the plant floor has transformed many industries, and plastics are no exception. As we move forward in Industry 4.0, big data and manufacturing analytics have the power to help the plastics industry grow exponentially.

But, how do you know which software to choose and which will ultimately help you grow?

The answer is, well, dependent on your goals as a manufacturer. We can’t tell you which software is going to be the best for your plant because it’s completely dependent on your needs. What do you want to achieve? What improvements do you need to make? Do you have a budget in mind? Will you have a dedicated person or team managing the software? What are your training needs? These, and many more, are questions that need to be pre-determined before selecting a software solution.

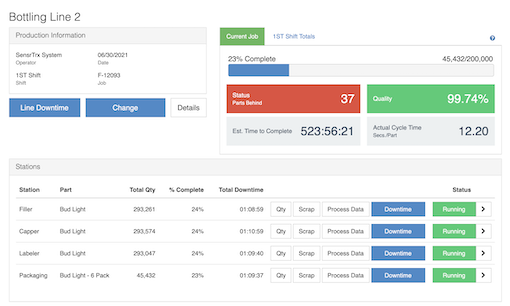

Of course, if you have questions, you can reach out to our team at Mingo or schedule a demo. We’re happy to help point you in the right direction even if, ultimately, Mingo is not the right fit for your company.