Production monitoring software is essential for achieving these goals for several reasons:

1. Improved Efficiency and Productivity

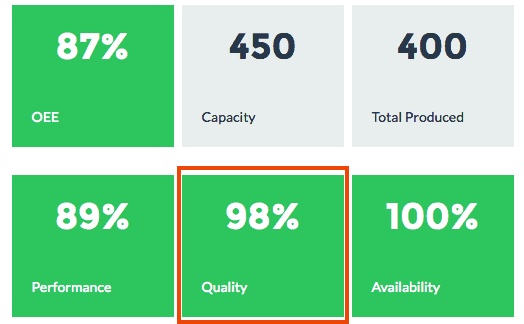

Production monitoring software provides real-time insights into the performance of machines and processes. By continuously tracking key performance indicators (KPIs) such as cycle times, machine uptime, and production rates, manufacturers can identify bottlenecks and inefficiencies. This enables them to optimize operations, reduce downtime, and increase overall productivity.

2. Enhanced Quality Control

Quality is paramount in metal forming. Production monitoring software helps maintain high standards by allowing for real-time quality checks and data collection. By monitoring critical parameters and comparing them against set standards, manufacturers can quickly detect and address deviations, reducing the risk of defects and ensuring that products meet customer specifications.

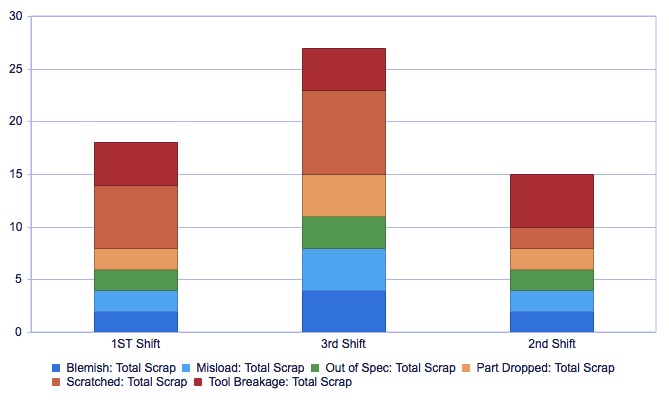

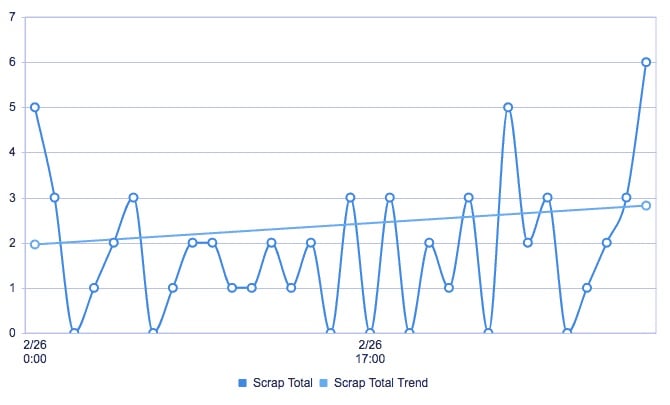

3. Reduced Waste and Scrap

Inefficiencies and errors in the production process can lead to significant waste and scrap, which directly impacts profitability. Production monitoring software helps identify and eliminate the root causes of waste, such as material inconsistencies or machine malfunctions. By minimizing scrap, manufacturers can reduce costs and improve their bottom line.

4. Predictive Maintenance

Unplanned machine downtime can be costly and disruptive. Production monitoring software supports predictive maintenance by analyzing data from sensors and equipment to forecast potential failures before they occur. This allows manufacturers to schedule maintenance activities during planned downtimes, reducing unexpected interruptions and extending the lifespan of their machinery.

5. Data-Driven Decision Making

Access to real-time data and analytics empowers manufacturers to make informed decisions. Production monitoring software provides comprehensive dashboards and reports that highlight trends, anomalies, and performance metrics. This data-driven approach enables managers to implement targeted improvements, allocate resources more effectively, and respond quickly to changing production conditions.

6. Regulatory Compliance and Traceability

The metal forming industry often requires adherence to stringent regulatory standards. Production monitoring software helps ensure compliance by providing detailed records of production activities, including material usage, process parameters, and quality checks. This traceability is crucial for audits and certifications, enhancing the manufacturer’s reputation and customer trust.

7. Flexibility and Scalability

As production demands evolve, manufacturers need systems that can adapt and scale. Production monitoring software is designed to be flexible and scalable, allowing manufacturers to integrate new machines, processes, and technologies seamlessly. This adaptability ensures that the software remains valuable as the business grows and production requirements change.

8. Enhanced Collaboration and Communication

Production monitoring software facilitates better communication and collaboration among different departments within a manufacturing facility. By providing a centralized platform for data sharing, it ensures that everyone, from operators to managers, has access to the same information. This alignment helps in coordinating efforts, troubleshooting issues, and driving continuous improvement.

9. Cost Savings

By optimizing processes, reducing waste, and improving machine utilization, production monitoring software can lead to significant cost savings. These savings can be reinvested into the business, supporting further innovation and growth.