Mandated by corporate to provide better reporting, the old way of tracking OEE and plant performance just wasn’t cutting it any more for one wire manufacturer.

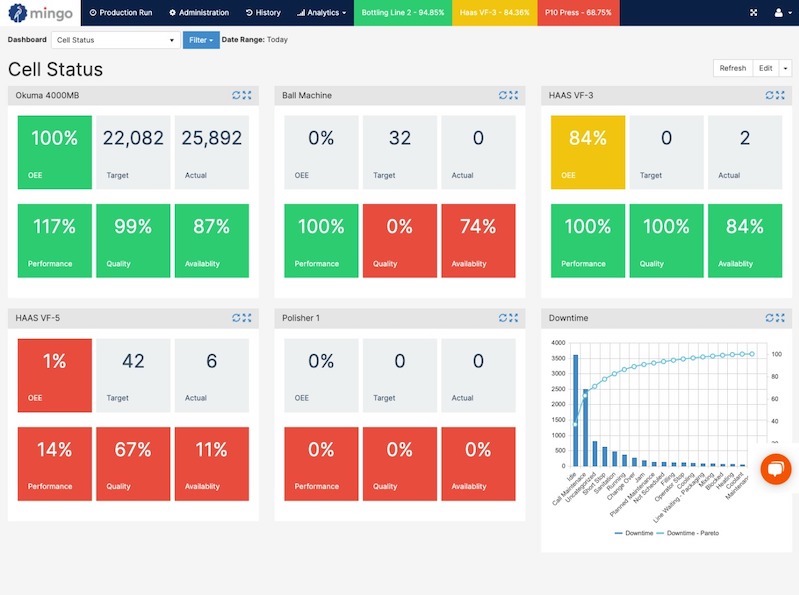

While widely regarded in the company as one of the most efficient plants in the fleet, they had no visibility into any inefficiencies that did exist, and no way to demonstrate their own productivity.

Using Banner Engineering’s wireless sensors, Mingo inexpensively and securely connected the manufacturers machines to measure cycle times and produce a reliable, realistic OEE.

These devices communicate over a private, secure wireless connection to the Mingo Gateway server, which in turn pushes data to the cloud. From the factory floor, a mix of newer and legacy machines now provides data on availability and cycle times.

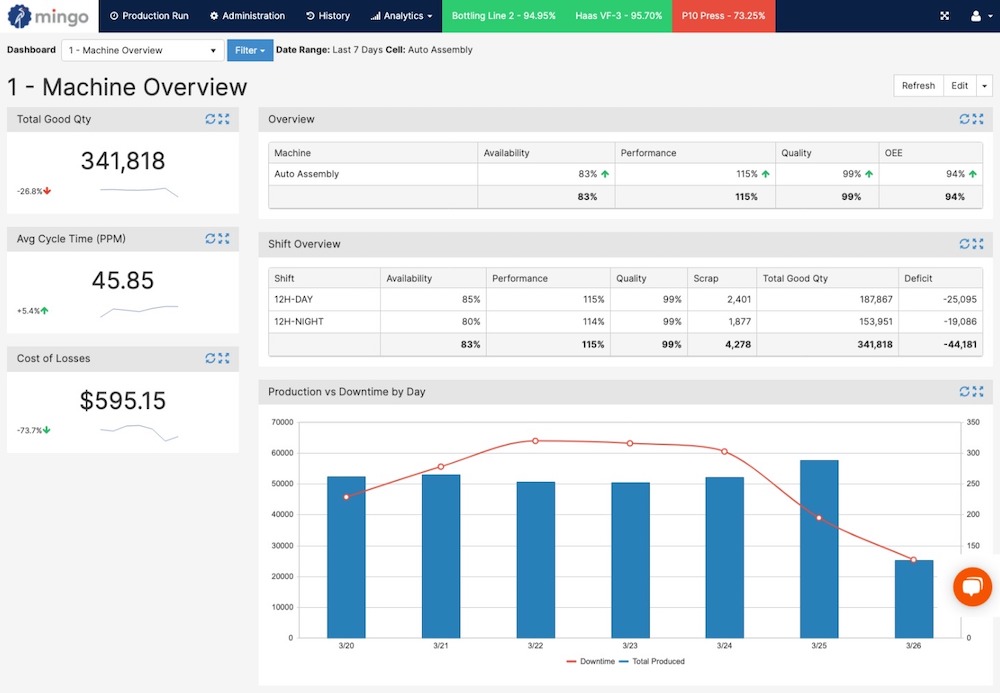

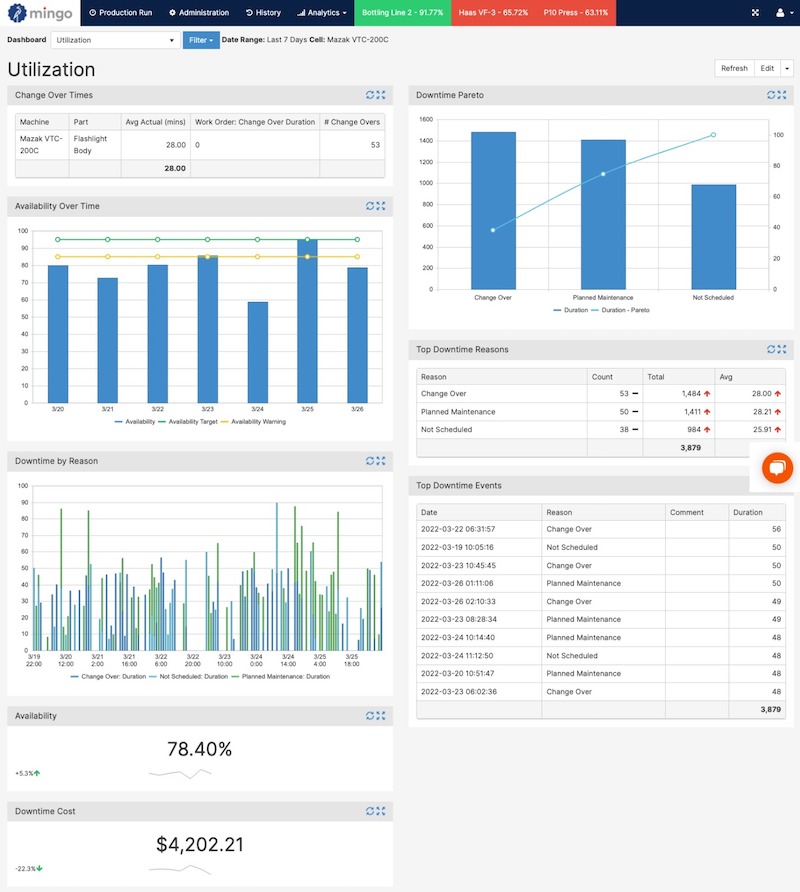

Mingo manufacturing analytics fulfills their reporting requirement and gives them critical insight into their manufacturing process. By weighing material before and after and inputting that data into Mingo, they can now track scrap rates to better perform.

Now, the wire manufacturer has plant-level visibility they can confidently pass on to corporate, proving out their peerless productivity with cold, hard facts.