There are typically 3 terms used to represent a cycle time, and as we said before, defining those terms varies from manufacturer to manufacturer.

1. Theoretical Max Machine Cycle – Maximum number of parts a machine can produce in a particular time period

2. Target Cycle Time – Time you would need to hit to deliver a product on time to customers (or downstream processes)

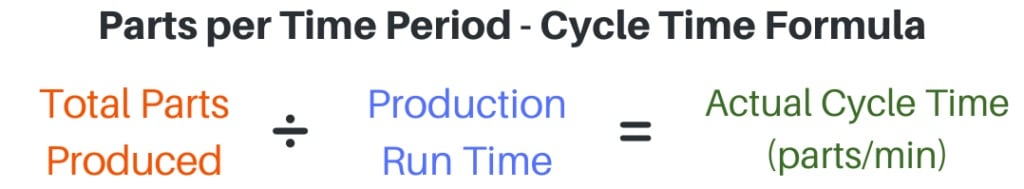

3. Actual Cycle Time – Time it takes to produce an actual number of parts or complete a “cycle”

We will show you how to calculate cycle time in any of the above units and how to convert it, too. From the list above, it may seem like there are 6 different cycle time calculator formulas but there are really only two: