“Everything that can be automated will be automated.”

– Robert Cannon, Robotics Professor Stanford University

IoT – The Internet of Things. Soon that term might seem like an irrelevant redundancy, like “Smart” Phone or “Mobile” Website or “Big” Data. The linguistic equivalent of a booster rocket falling off a space-bound vehicle. And good riddance.

Like a lot of the terms we read about on industry blogs, in articles or hashtag on social, #IoT is shorthand for a convenient umbrella-concept encompassing a bundle of concepts. Namely it refers to physical objects using sensors and devices connected to a private or public network by some person for some reason. Alternative definitions abound, so you can take your pick.

For consumer markets, IoT will transform our lives by providing the convenience of making formerly dumb things, e.g. doorbell (canvasser rang it at 10:05 while you were at work), thermostat (68 degrees), oven (off) or car keys (under the mail on the table), connected to the internet so that us smart people know where they are and what they are doing.

For industrial manufacturers, however, IoT means thinking much differently about your machines and how are they operate. It means monitoring equipment remotely, perhaps one day operating them remotely, and maybe not too far in the future, allowing them a degree of semi-autonomous control to operate themselves.

IoT is the promise of factories running at near 100% capacity, 24/7, with a high degree of reliability because the machines are part of an automated maintenance system and a fully integrated supply and logistics pipeline, all of it connected by a variety of IoT communication platforms and cloud computing.

It’s a big opportunity, so it’s worth taking the time to parse out what these IoT platforms will actually provide.

What is an IoT Platform, Anyway?

The two biggest on the market right now being Amazon and Azure, so we’ll focus on them but there’s a load of other IoT providers out there and you can see them here.

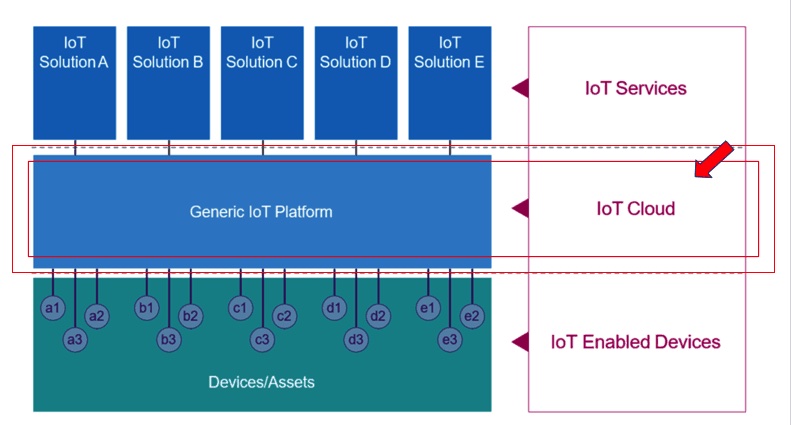

What these platforms all have in common is that they are comprised of four necessary component architecture:

- Hardware (devices and sensors)

- Connectivity through a router, gateway, wi-fi, satellite, ethernet, etc.

- Software

- User interfaces

IoT = Cloud w/ Devices

IoT Platforms aren’t anything new, they are essentially the same cloud computing services we’re all familiar with. AWS and Azure IoT work the same way. They both provide a set of tools and resources available by subscription and provisioned in their massive cloud architecture.

Our own cloud software runs on Amazon Web Services. This means that enterprising folks like us can design and build an application, host it on Amazon’s servers, integrate an entire suite of application development and application lifecycle management tools around it, and then offer the application to our customers for an affordable price anywhere in the world. It also means we can scale rapidly without losing performance, jeopardizing data security or costing us millions of dollars in computer hardware and electricity bills. Hallelujah to the cloud!

What AWS does not provide us is everything else that makes Mingo what it is, which is to say, like 98%. Essentially, while providing valuable tools, an IoT Platform will be the host for all the solutions you’ll have to build yourself. See In Manufacturing Analytics Build vs. Buy Dilemma Is Actually Now vs. Later for some perspectives on the custom route.

In the future, IoT platforms will no doubt prove immense value by providing ready-made integration points between apps, like a Zapier or Jitterbit does today, and there will be some value-added when a platform provides a curated marketplace of tested and trusted apps that can be easily provisioned. An example might be something like Siemens’ MindSphere IoT product which we’ve integrated Mingo to, or the way Go Daddy or WordPress provide seamless installation, but the point is, purchasing an IoT service package won’t take away the need to either custom build a solution or buy the software you’ll want and need.

So, What does an IoT Platform provide?

Basically, if there were an unboxing video on YouTube of a person setting up Amazon IoT on their factory floor it wouldn’t get many followers since it would feature an empty box

The service these platforms provide isn’t specific to any one use case or industry or person or device. It’s called a platform specifically because it’s not purpose-built for any one thing. It’s something you will have to build on top of.

Let’s go back to that list and see what you’ll actually get from implementing Amazon IoT as your manufacturing analytics provider:

Hardware – Nope. You will have to connect to your machines PLC, install 3rd party PLC or external sensors.

Connectivity – Nope. You will still need to push data from the sensors through your own network to get to the cloud which means installing a server to act as a gateway or your edge server.

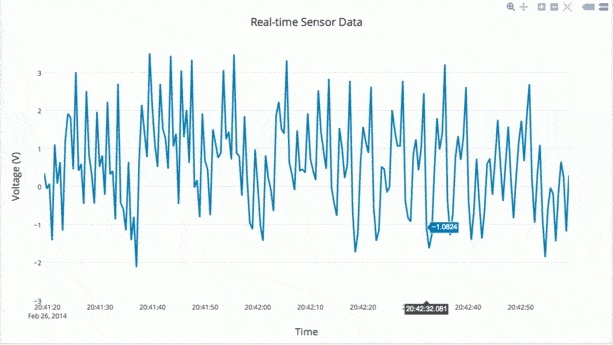

Software – Well, in a sense. You can use AWS products like Kinesis to capture a stream of data. Here’s what it will look like (and this is with visualization software) – a squiggly line running across our screen in real-time. The issue with data stream is that it tells us practically nothing, other than that the device is streaming a lot of data at you.

Just because you have the power to connect a sensor to the internet and stream data won’t mean much, at least not without a lot of work on your part. That’s because there won’t be any context for your data. Context in machine analytics means machine and operator data is associated with a production record that references a machine name, the exact time of day, the part being produced, the shift and the operator, etc. In other words, for effective analytics, context is everything.

Most of what you get is middleware, amazon software you use to put data in Amazon databases or push to mobile applications, which you will have to build and maintain yourself.

User Interfaces – Nope. If you want your operators to tell you what’s happening in real-time, you will have to build UI to capture operator data and merge that data with the machine data. If you want to see that data together, you’ll have to build some sort of dashboard or table view and if you want to be able to see your data differently, say comparing two similar machines on two different lines for instance, you will have to build a way for your user to choose that view over the other view.

An IoT platform will give you the middleware, but you’ll still have to physically connect up your machines and sensors, install and configure a gateway device, write the code to pull and capture the data streams, write the code that manages the data and contextualizes it, write the algorithms that turn that data into useful KPIs, write the code that displays within a user interface, and oh yeah, you’ll most likely need to develop some code and a UI to capture what the operators are doing as well, since if a machine is down it might be able to tell you what the reason is or it might not, but just as likely, someone might have just switched it off and you’ll want to know why.

Basically, if there were an unboxing video on YouTube of a person setting up Amazon IoT on their factory floor it wouldn’t get many followers since it would feature an empty box.

IoT and Standalone Analytics

Since we are in the business of connecting devices, specifically the machines on the factory floor, our manufacturing analytics software often gets lumped into a general class of services called IoT platforms or solutions.

Mingo is, technically, an IoT platform, but we’re pre-built and purpose-built for analytics which makes us really good at what we do: Mingo connects machines through sensors or internal hardware and operator input by way of an operator UI to a gateway connected to the cloud where it streams the data. This data is then aggregated into meaningful contextual analytics displayed in dashboard Pareto Charts and tables in a simple to understand user interface.

Subscribing to any of the IIoT platforms out there won’t get you this. So all the hard work we’ve put into Mingo, you can either build it over again or end up buying a manufacturing solution later.

The point we’d like to make is. If you are investing in an IoT platform as part of your long-term strategy, then recognize that data will drive it, and analytics (data within context) will be the amplifier that provides value to every application you run on it.

Mingo will power IoT with data. No (custom) assembly is required.

What Data Do I Need?

For many manufacturers, the question they should be asking themselves isn’t what they should build on an IoT platform, but rather what data do they need to see from the factory floor:

“Do I want to track downtime by reason?”

“Do I want to be able to tie performance to quality and scrap?”

“Do I want to see all your production KPIs by machine, by cell, or by department?”

“Do I want to gain valuable input from your operators on the plant floor?”

“Do I want to track costs per part and see those costs in relation to availability, performance, and quality?”

If the answer is yes to any of these, you should take a look at Mingo, a solution designed specifically to:

- Monitor machines in real-time

- Provide operators an easy way to identify and report downtime

- Facilitate root-cause analysis and troubleshooting

- Track production KPIs impacted by availability, performance, and quality