Every business wants a return on investment, and an investment in manufacturing analytics is no different.

But, success with manufacturing analytics doesn’t look the same for everyone. If you were to ask ten of our clients what they were originally looking to accomplish with Mingo Smart Factory, you might receive ten different answers.

In some companies, the focus is cost reduction while for others, it’s increased revenue. It’s easy to assume that machine availability will contribute to increased revenue, maybe it’s scrap, or it’s throughput, and it’s true that machine data analytics can help solve those specific issues.

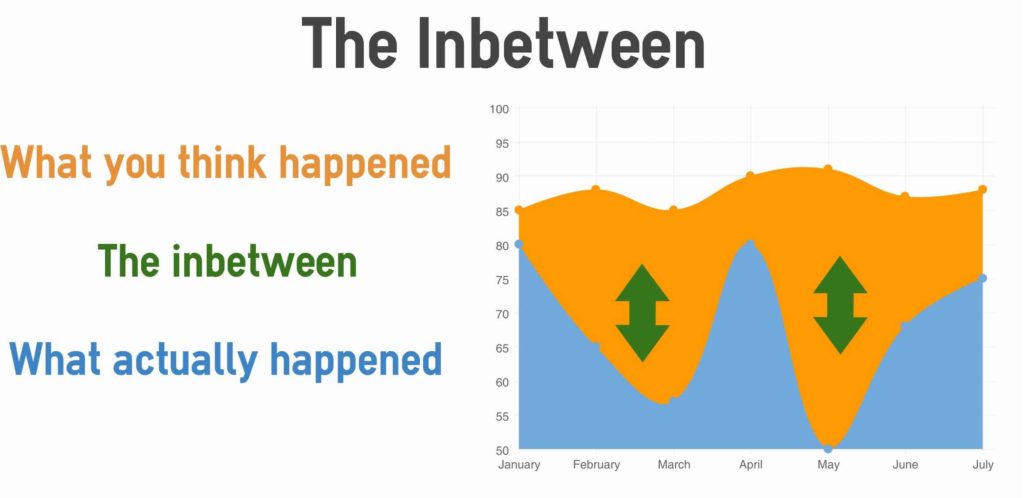

What we’re finding, though, is that just because we have a customer who was able to increase their throughput by 30%, doesn’t mean that everyone else can do the same. It’s all relative.

Which makes you ask yourself, “What is the ROI for my company, specifically?”

If you know manufacturing analytics is the solution for the problems you’re facing on the floor, and you know it will prove to be successful for continuously improving, how do you prove ROI?

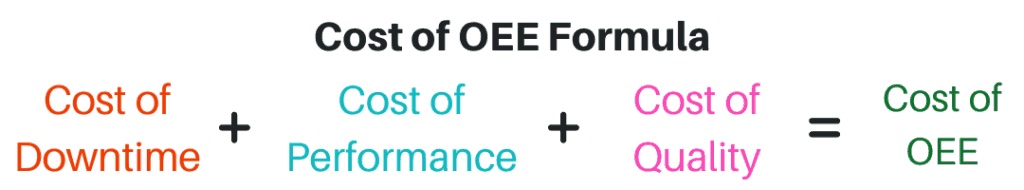

Below, we will look at each component in detail and determine how to calculate ROI in your factory. With formulas and examples, you’ll have that answer in no time.

ROI calculations can get very complex when trying to model exactly what happens in the business. As you go through the ROI calculator, remember that the formulas and examples serve as guidelines and are not conclusive.