The Pitfalls of High OEE: Understanding True Productivity

Despite its widespread use as a performance metric in manufacturing, relying solely on Overall Equipment Effectiveness (OEE) to gauge productivity can be misleading. OEE is a composite metric that factors in equipment availability, performance, and quality to assess operational efficiency. In this blog post, we’ll explore why your productivity can still suffer despite a high OEE, the process of calculating OEE, the limitations of depending on OEE for measuring productivity, and the importance of a production monitoring system in accurately measuring productivity.

Why Your Productivity Can Still Suffer with a High OEE

A high OEE does not necessarily equate to optimal productivity. Here’s why:

- Focus on Equipment Efficiency: OEE primarily measures the efficiency of individual equipment or processes. It can overlook broader factors that impact overall productivity, such as workflow bottlenecks, material handling inefficiencies, and manpower utilization.

- Neglect of Non-Production Time: OEE calculations often exclude non-production time, such as setup, changeover, and maintenance periods. These factors can significantly impact overall productivity.

- Quality Over Quantity: While OEE accounts for quality losses, it prioritizes quality over quantity. This can potentially mask instances where increased production volume is essential for meeting demand.

The Process of Calculating OEE

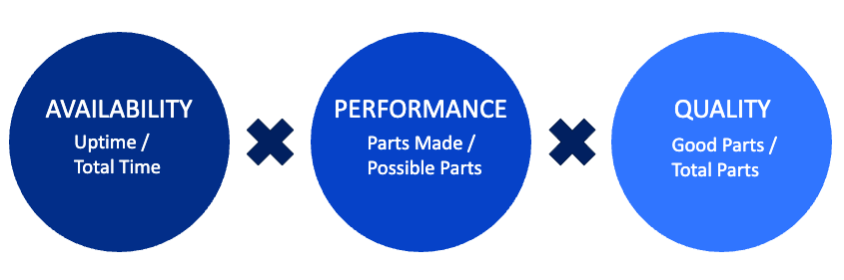

Calculating OEE involves multiplying three key factors: Availability, Performance, and Quality. Each factor is expressed as a percentage and multiplied together to obtain the overall OEE percentage.

- Availability: Availability measures the percentage of time equipment is available for production, calculated as (Operating Time / Planned Production Time) × 100.

- Performance: Performance evaluates the efficiency of equipment compared to its theoretical maximum output, calculated as (Actual Production Rate / Ideal Production Rate) × 100.

- Quality: Quality assesses the ratio of good parts produced to total parts produced, calculated as (Good Parts / Total Parts) × 100.

Limitations of Depending on OEE for Measuring Productivity

While OEE provides valuable insights into equipment efficiency, these insights can be misleading when used as the sole measure of productivity. Here are a few limitations to keep in mind:

- Single-Dimensional View: OEE focuses narrowly on equipment performance and does not account for broader operational factors that influence productivity, such as process flow, inventory management, and workforce efficiency.

- Incomplete Picture: OEE calculations may overlook downtime events, setup times, and other non-production activities that impact overall productivity, leading to an incomplete assessment of performance.

- Inability to Identify Root Causes: OEE alone may not pinpoint the root causes of productivity losses. An OEE number may go up or down without clearly defining why. This can make it challenging to implement targeted improvements and drive continuous optimization.

The Importance of a Production Monitoring System When Measuring OEE

To accurately measure productivity and identify opportunities for improvement, manufacturers need a comprehensive production monitoring system like Mingo Smart Factory. Such a system provides real-time visibility into equipment performance, downtime events, production metrics, and other key indicators of productivity.

By integrating data from various sources and analyzing it holistically, a production monitoring system enables manufacturers to:

- Identify and address inefficiencies in equipment utilization, setup times, and changeover procedures.

- Track overall equipment effectiveness alongside broader productivity metrics to gain a comprehensive understanding of performance.

- Implement data-driven strategies for optimizing workflow, reducing downtime, and maximizing throughput.

Use OEE as a Goal, Not the Gold Standard

While OEE is a valuable metric for assessing equipment efficiency, but it can be misleading if it is relied upon as the only measure of productivity. Understanding the limitations of OEE and complementing it with a robust production monitoring system is essential for gaining a comprehensive view of productivity and implementing targeted improvements to drive operational excellence. With the right tools and insights, manufacturers can optimize performance, minimize downtime, and achieve their productivity goals effectively.