What is Good OEE?

The true value of good OEE comes from implementing a systematic approach to measurement and improvement.

Automotive

Versatech Increased OEE 30%

Consumer Package Goods

Oral Biotech Eliminated Scrap

Food/Beverage

Louisiana Fish Fry Increases OEE 12%

Metal Stamping

H&T Waterbury Reduced Downtime 71%

Blow Molding

Lyons Blow Molding Automated Reporting & Labeling

Mingo Smart Factory is a simple OEE software that is fast to deploy. Get visibility and insight into production with manufacturing analytics.

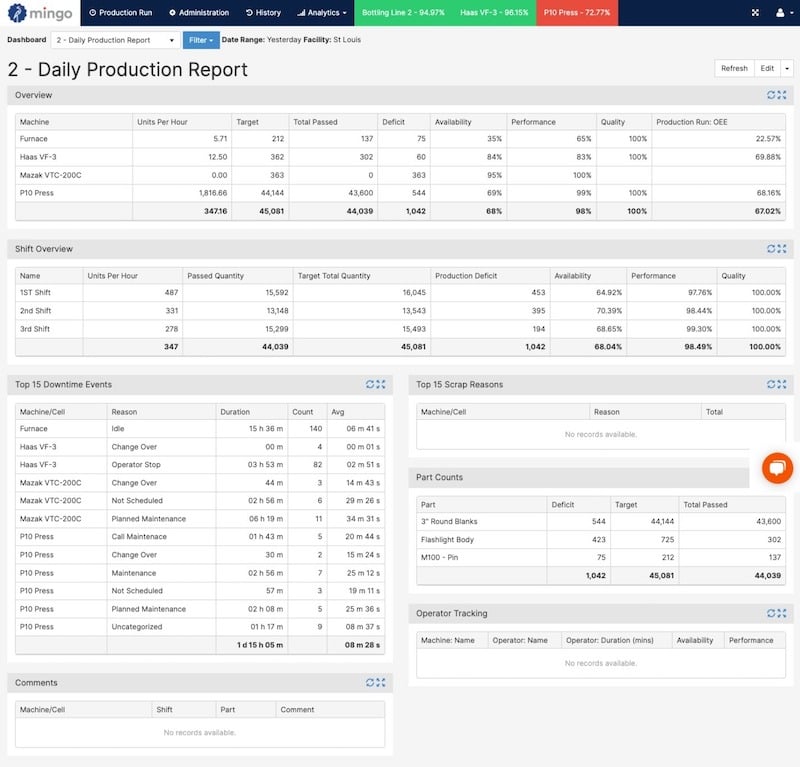

Overall Equipment Effectiveness is a vital metric used by manufacturers to assess the performance of their equipment and improve production processes. This software provides a comprehensive solution to measure and analyze this metric in real-time, enabling businesses to identify and address inefficiencies promptly.

In today’s fast-paced manufacturing landscape, companies are constantly looking for ways to optimize their operations and maximize productivity. One tool that has gained significant attention and proven to be effective in achieving these objectives is OEE software. By understanding the concept of OEE software and its key features, manufacturers can implement it in their operations to enhance efficiency and drive overall success.

When it comes to manufacturing, efficiency is key. Every minute of downtime or underperformance can result in significant losses for businesses. This is where OEE software comes into play. By implementing OEE software, manufacturers can gain valuable insights into their equipment’s availability, performance, and quality, allowing them to make real time data-driven decisions to optimize their operations.

In today’s competitive industry, maximizing efficiency is critical to stay ahead of the competition. OEE plays a pivotal role in achieving this objective by providing a comprehensive evaluation of equipment performance.

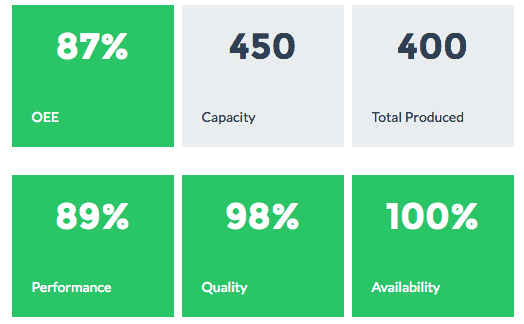

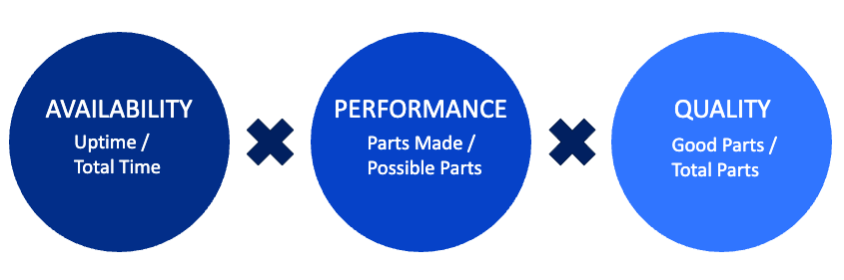

By measuring and analyzing OEE, manufacturers can gain a deeper understanding of their equipment’s effectiveness. This includes evaluating its availability, performance, and quality. By assessing these aspects, businesses can identify bottlenecks and implement measures to optimize their operations, resulting in increased productivity and reduced downtime.

For example, if a manufacturing plant has a low OEE score due to frequent breakdowns or equipment failures, the software can help identify the root causes of these issues. This information can then be used to implement preventive maintenance schedules or invest in new equipment to improve overall efficiency.

Production monitoring software provides real-time monitoring and reporting of OEE metrics, allowing manufacturers to track their equipment’s performance on an ongoing basis. With this information at their fingertips, businesses can make informed decisions to drive continuous improvement and maximize their overall equipment effectiveness.

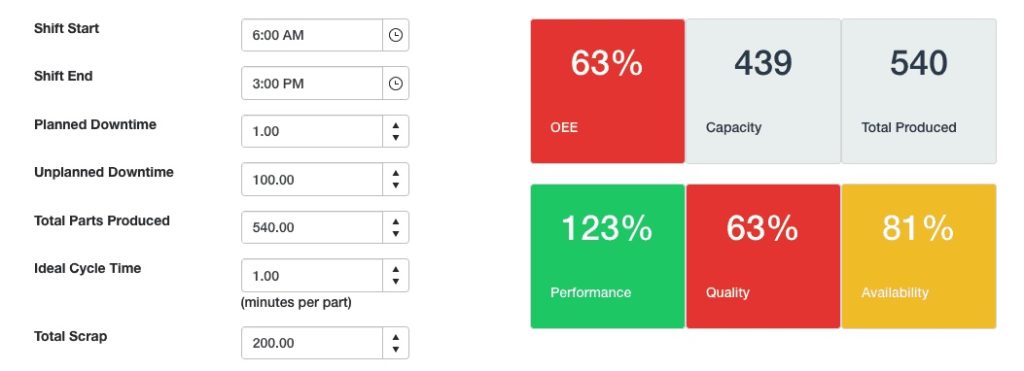

What is your factory’s current efficiency? Try Mingo Smart Factory’s OEE Calculator.

OEE software offers a range of features designed to streamline operations and maximize productivity. By utilizing these features, businesses can gain a comprehensive understanding of their equipment and processes, enabling them to make informed decisions and drive continuous improvement. It empowers manufacturers to optimize their operations, increase productivity, and ultimately, achieve higher profitability.

OEE software provides manufacturers with up-to-date information on their equipment’s availability, performance, and quality. This allows them to identify any issues or inefficiencies promptly and take appropriate actions.

OEE software can automatically collect data from different sources, such as sensors, machines, and production lines. This eliminates the need for manual data entry, reducing the risk of errors and saving valuable time.

OEE software often includes visualization tools, such as charts and graphs, to help manufacturers analyze and interpret their OEE data effectively. These visual representations make it easier to identify trends, patterns, and areas for improvement.

OEE software can seamlessly integrate with existing systems and equipment, such as ERP (Enterprise Resource Planning) systems and SCADA (Supervisory Control and Data Acquisition) systems. This integration enables manufacturers to leverage their existing infrastructure and data sources, making implementation smoother and more efficient.

OEE software can send alerts and notifications to relevant personnel when performance issues or deviations from target OEE values are detected. This allows for immediate action to be taken, minimizing the impact on production and preventing further losses.

OEE software has a significant impact on manufacturing efficiency by enhancing operational performance and driving productivity. Let’s explore how businesses can leverage this software to optimize their operations and achieve their efficiency goals.

Efficiency is a crucial factor for businesses across industries. It directly affects their bottom line and overall competitiveness in the market. OEE software offers a comprehensive solution to improve efficiency by providing real-time insights into equipment performance and enabling data-driven decision-making.

By continuously monitoring key metrics such as availability, performance, and quality, businesses can proactively identify issues and take corrective actions promptly. This proactive approach minimizes downtime, reduces waste, and improves overall equipment effectiveness.

For example, imagine a manufacturing plant that utilizes OEE software to monitor its production line. The software tracks the availability of each machine, the speed at which they operate, and the quality of the output. If a machine experiences a sudden drop in performance, the software immediately alerts the maintenance team, allowing them to address the issue before it leads to a complete breakdown. This proactive maintenance approach not only saves time and resources but also ensures uninterrupted production.

Furthermore, OEE software enables businesses to analyze historical data and identify patterns or recurring issues that may hinder efficiency. By understanding the root causes of inefficiencies, organizations can implement targeted improvements and optimize their operations. This continuous improvement cycle helps businesses achieve higher levels of operational efficiency over time.

OEE software plays a vital role in driving productivity by optimizing equipment utilization and reducing bottlenecks. By identifying and addressing factors that limit production capacity, businesses can maximize the output of their equipment, resulting in increased productivity. Additionally, OEE software enables businesses to track and analyze production trends, facilitating data-driven decision-making for further improvements.

Consider a logistics company that utilizes OEE software to manage its fleet of vehicles. The software provides real-time data on each vehicle’s performance, including fuel consumption, average speed, and delivery times. By analyzing this data, the company can identify underperforming vehicles or routes and take corrective actions, such as optimizing routes or providing additional training to drivers. These improvements not only increase productivity but also enhance customer satisfaction through faster and more reliable deliveries.

Productivity software allows businesses to set performance benchmarks and track their progress towards achieving them. This goal-oriented approach motivates employees and fosters a culture of continuous improvement. By visualizing their performance in real-time, employees can identify areas for growth and take proactive steps to enhance their efficiency.

OEE software is a powerful tool that enhances operational efficiency and drives productivity. By providing real-time insights into equipment performance, enabling proactive maintenance, and facilitating data-driven decision-making, businesses can optimize their operations and achieve their efficiency goals. Embracing OEE software empowers organizations to stay competitive in today’s fast-paced and demanding business landscape.

To measure the success of your OEE software implementation, track key performance indicators such as overall equipment effectiveness, downtime reduction, increase in production output, and cost savings achieved through enhanced efficiency. Regularly assess these metrics to evaluate the return on investment and identify areas for further improvement.

“[Mingo Smart Factory] was obviously designed by those with significant manufacturing experience as opposed to some software guys deciding to target manufacturing. Their knowledge of how manufacturing actually works comes through.”

President & General Manager, Custom Rubber Products

“What gets tracked, gets improved.” Matt Hill, Operations Improvement Coordinator at H&T Waterbury

“Reduction in overtime was exactly what we were looking to do… and that’s exactly what we have achieved.”

Chad Hill, CEO at Versatech

“The real-time reporting at the manufacturing level is the biggest benefit.”

Ben Wohlschlaeger, Business Process Optimization Manager at Tacony

“Now that we have the transparency into the process, our OEE availability has increased significantly.”

John Bowers, VP of Operations at Oral BioTech

While implementing OEE software is a significant step towards enhancing efficiency, maximizing its benefits requires adopting best practices.

1. Evaluate your current processes: Before implementing OEE software, assess your existing processes to identify areas for improvement and determine the specific goals you want to achieve.

2. Select the right software: Research different OEE software options available in the market and choose the one that aligns with your business needs and objectives.

3. Define key performance indicators (KPIs): Establish clear KPIs based on your specific requirements. These KPIs will serve as benchmarks to measure the success of your OEE software implementation.

4. Implement the software: Work closely with the software provider to implement the OEE software seamlessly into your existing systems and equipment.

5. Train your workforce: Provide comprehensive training to your employees to ensure they understand the software’s functionality and how to utilize it effectively.

6. Monitor and adjust: Continuously monitor the performance of your OEE software and make necessary adjustments to optimize its effectiveness.

Implementing OEE software may come with challenges. Some common challenges include resistance to change, integration complexities, and data management. To overcome these challenges, businesses should foster a culture of continuous improvement, involve employees in the implementation process, and work closely with the software provider to address any integration or data-related concerns.

The “World-Class OEE” term is credited to Seiichi Nakajima, author of “Introduction to TPM: Total Productive Maintenance”. In that book, he explains how to implement TPM and OEE. Since the term was coined in 1984, manufacturers across the globe have clung to the world-class OEE benchmark as a guiding principle. While, it is good to have guiding metrics, experts agree that basing your company’s success off one, flawed metric can be detrimental. Each company must find the OEE number that works for them and not rely on a flawed metric or a pre-determined “world-class” number. OEE should only be used to measure a single cell or machine and not applied across the factory because it can largely differ from line to line or machine to machine. Cycle times also vary from plant to plant.

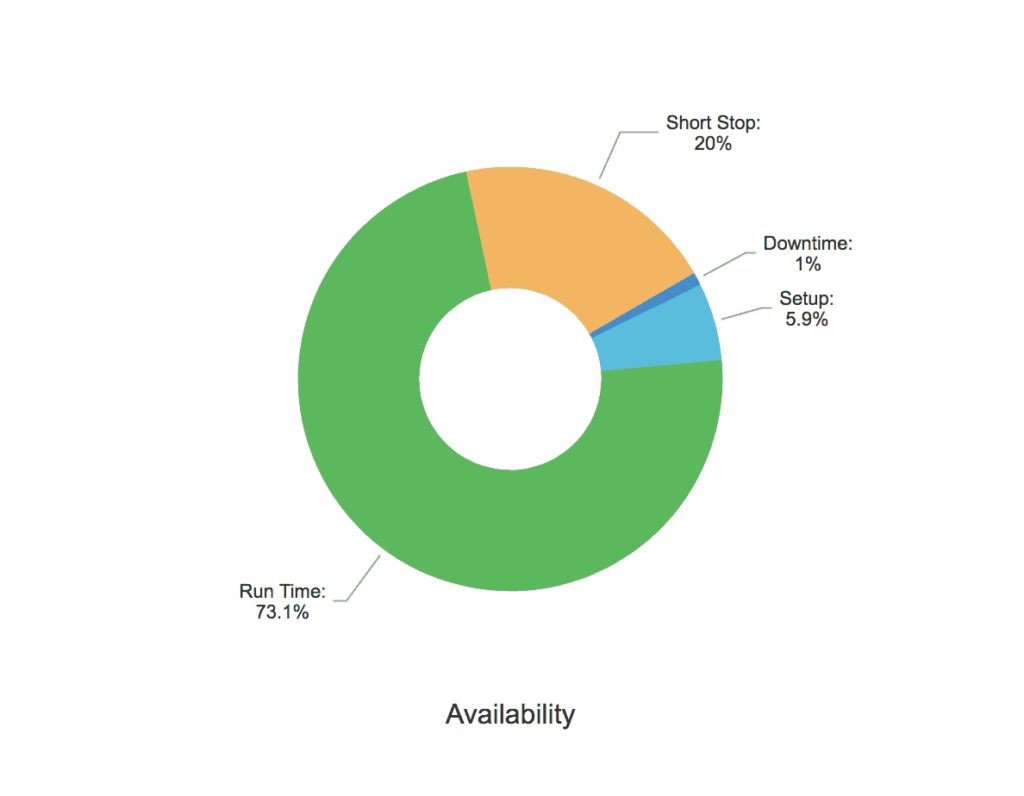

No other part of the Overall Equipment Effectiveness OEE calculation gets manipulated more than availability. Many companies will manipulate planned and unplanned downtime to achieve a high availability number and overall OEE. Companies do this to reach an industry-accepted OEE, such as 85%. Louisiana Fish Fry, one of Mingo Smart Factory’s customers, recently found that while one of their lines had excellent OEE metrics, their availability was limiting their output.

Each company should pick a methodology that tracks the true availability of the machine. For example, should breaks be planned or unplanned downtime? Can the machine continue to run during the break? If so, it should be unplanned. These efforts shouldn’t be focused on achieving an arbitrary number.

Get the software up and running in less than 1 day and immediately get visibility into the plant.

Get insight into important KPIs like OEE, cycle time, downtime, utilization, throughput, and more.

See how the plant is doing in real-time with scoreboards, dashboards, and a mobile app.

Start small and as you grow, expand to a full manufacturing analytics platform.

*According to a case study from Tacony Corporation. **Individual results may vary

The future of efficiency lies in embracing cutting-edge technologies, and OEE software is set to play a significant role in this transformation. Let’s explore some predicted trends in OEE software that businesses should be aware of.

1. Enhanced connectivity: OEE software will become more interconnected with other manufacturing process systems, enabling seamless data exchange and integration.

2. Advanced analytics capabilities: OEE software will leverage advanced analytics techniques such as machine learning and predictive modeling to provide more accurate insights and proactive optimization recommendations.

3. Real-time remote monitoring: Remote monitoring capabilities will be further enhanced, allowing businesses to monitor equipment performance from anywhere, facilitating proactive maintenance and issue resolution.

As businesses continue to leverage OEE software to enhance efficiency and drive productivity, the long-term impact will be significant. With greater visibility into their operations, businesses will be able to make data-driven decisions, optimize processes, and achieve continuous improvement. This, in turn, will lead to increased competitiveness, cost savings, and overall success in the dynamic manufacturing landscape.

In conclusion, adopting OEE software is a crucial step for businesses aiming to boost efficiency, streamline operations, and maximize productivity. By understanding the concept of OEE software, harnessing its key features, and implementing it effectively, businesses can gain a competitive edge and thrive in the rapidly evolving manufacturing industry. Embrace the power of OEE software and unlock your operations’ true potential for success.

Are you ready to take the next step in improving OEE in your facility? Contact Mingo Smart Factory today!

Mingo Smart Factory is the easiest to use manufacturing productivity platform that provides real-time production monitoring on the factory floor, improves on-time delivery, and increases profitability of manufacturing companies. It is fast to deploy and easy to use.

The true value of good OEE comes from implementing a systematic approach to measurement and improvement.

Downtime can be defined as periods when machinery or other systems are not productive, often leading to a decrease in overall productivity. This article will

Downtime refers to the period when production is halted, directly impacting a company’s output and revenue. It can occur for various reasons, including machine failures,

Understanding and calculating downtime is crucial for optimizing manufacturing operations and enhancing productivity. Downtime not only impacts a shop’s output but can also bleed resources

One significant factor in operational efficiency is understanding and addressing downtime. Downtime refers to periods when a system or equipment is not operational or is

Understanding and calculating downtime in your Plex manufacturing environment is crucial for improving overall efficiency. By knowing how much time is lost due to various factors, organizations

Built by people who know manufacturing, Mingo Smart Factory provides the 21st century “Smart Factory” experience that manufacturers need to grow in a modern environment. See how it can help you drive revenue.

© Copyright 2025 Mingo Smart Factory » Privacy