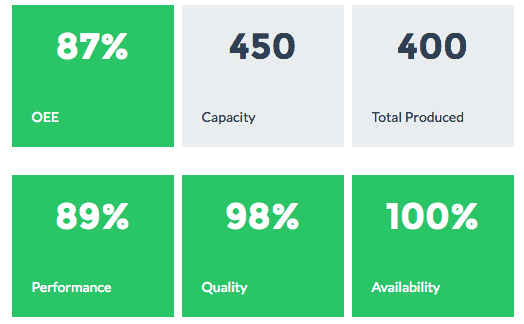

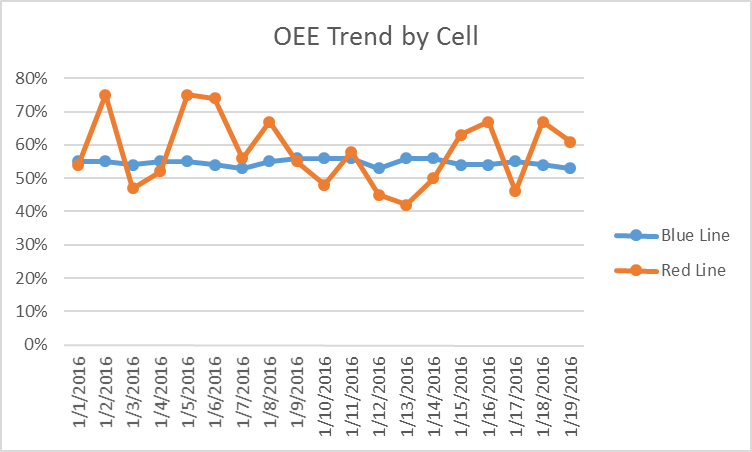

Measuring Overall Equipment Effectiveness is a great thing and the visibility it creates can help improve equipment efficiency across the plant. But OEE is missing one critical element – cost. It is not a measure of the profitability of a machine. In certain situations, you may have a very low number of 30% but the machine is profitable, the converse may be true as well. A machine may run at 80% OEE but not be profitable.

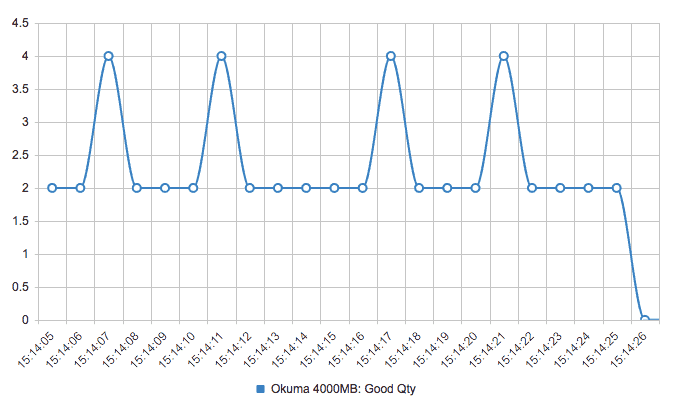

Unfortunately, most companies don’t have unlimited funds to create the ideal manufacturing environment. Companies have to make a tradeoff between being efficient and being cost-effective. For example, the most efficient way to run a certain part with multiple operations is through a cell. But if that part is only run every other week? The company cannot justify setting up a dedicated cell. So the machines that run this part will have a lower OEE because of setup, change over, and startup time but will still be profitable.