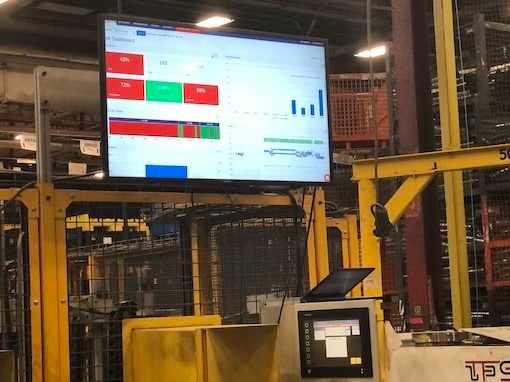

Choosing a software solution to help you increase efficiencies and improve productivity in the plant is a very unique process. You have goals you need to achieve and deadlines to meet so whichever software you choose, has to help you do that. While we encourage you to explore everything Mingo has to offer, you need to have an idea of what you want to accomplish before actually selecting software.

There are particular questions you need to consider before moving forward. What is your price point? Does the software fit within your budget? What is the implementation process like? Do you need someone to spearhead the project or will the company handle that? Specifically, how will it help you achieve your goals? Have they worked with manufacturers in your industry before? While these are only a few examples, there’s a lot of research that needs to be done before signing on the dotted line.

However, Mingo can provide visibility to the following industries: food, beverage, including soda or soft drinks, bottled water, pet food, breweries, etc. Mingo’s focus is not limited to one particular industry but can be applied to virtually any food manufacturing or beverage manufacturing industry. If you have any questions, please don’t hesitate to reach out to our team of manufacturing experts. We’re happy to help.

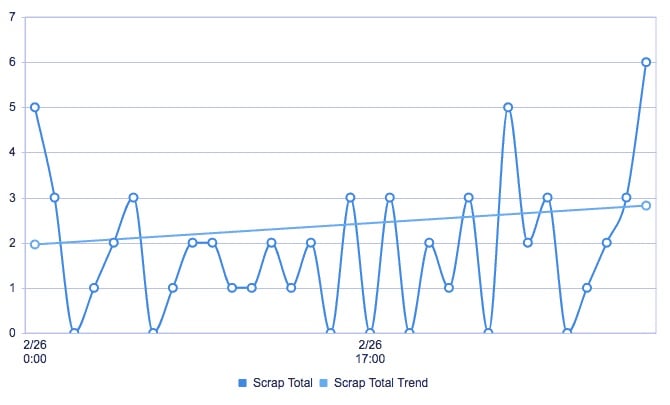

Look closely at is exactly why you were able to increase OEE. If you fully understand the mechanisms behind the increase you can determine if improvements are permanent, seasonal, or part of a larger, more complex process, etc. Knowing this information could help you make improvements in other parts of your business.