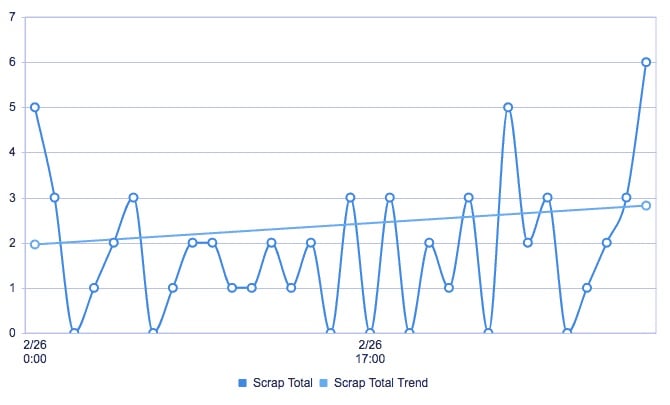

How do you understand what’s happening, what’s working, and what’s not on the plant floor? Without insight into how your machines are running, it is difficult to improve processes, and subsequently, your business. As an injection molding manufacturer, how can you consistently innovate your product without the smart technology needed to provide those innovations? Quite frankly, you can’t. Embracing and implementing an injection molding software solution is the answer.

But, how do you know which software solution is going to be the best for your company? It all comes down to the goals you want to accomplish and determining if the software vendor can help you accomplish those goals.

Will a software company help you gather and understand your data to continuously improve? If yes, they may be a good fit for your needs. The visibility challenge becomes a thing of the past.

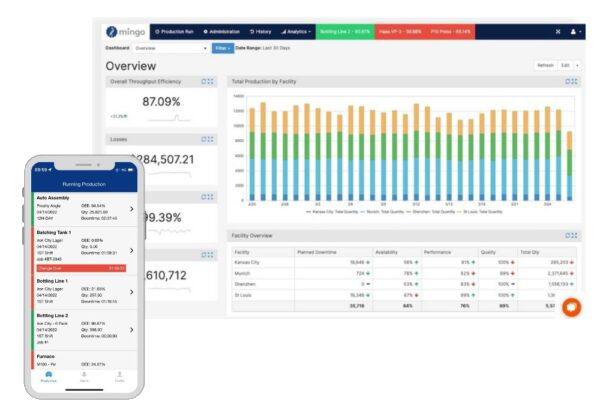

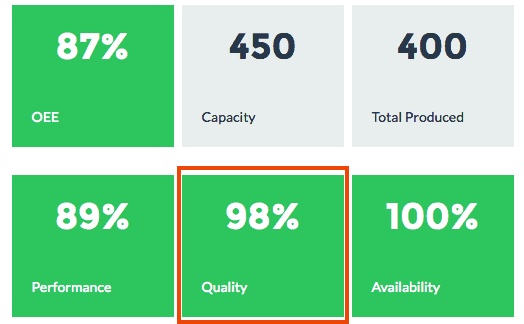

Injection molding software is a big data solution that can create insights and provide visualization capabilities that will further clarify data gathered if they align with your goals.