Replace Manual Reporting is a solution that automates the manual data collection and reporting process, reducing time, errors, and manual labor associated with manual reporting. The solution works by connecting to equipment and automatically collecting data, which is then processed, analyzed, and reported in real-time.

Replace Manual Reporting works by connecting to equipment and collecting data automatically, eliminating the need for manual data entry. The data is transmitted to a central system where it is processed, analyzed, and reported in real-time. This eliminates the manual process of data collection and reporting, reducing time and errors associated with manual reporting.

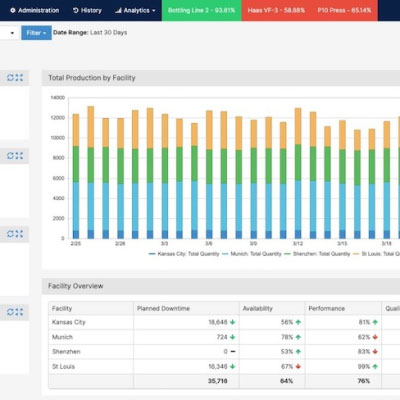

Replace Manual Reporting offers several benefits, including improved accuracy, increased efficiency, reduced manual labor, and increased visibility into operations. The automation of the data collection and reporting process eliminates the possibility of human error, providing accurate data in real-time. This increased accuracy can lead to improved decision-making, increased efficiency, and reduced manual labor. The solution also provides increased visibility into operations, allowing for a better understanding of production and performance.

Replace Manual Reporting eliminates the possibility of human error during data entry and reporting, providing accurate data in real-time. In manual reporting, errors can occur during data entry or when data is being reported, leading to inaccurate information. Replace Manual Reporting eliminates this risk, providing accurate data that can be used for informed decision-making.

Yes, Replace Manual Reporting can be customized to meet specific needs and requirements, providing tailored data collection and reporting solutions. The solution can be configured to collect and report data from specific equipment and can be integrated with existing systems to provide real-time reporting. This customization allows for improved decision-making and increased efficiency, providing a solution that meets the specific needs and requirements of your operations.

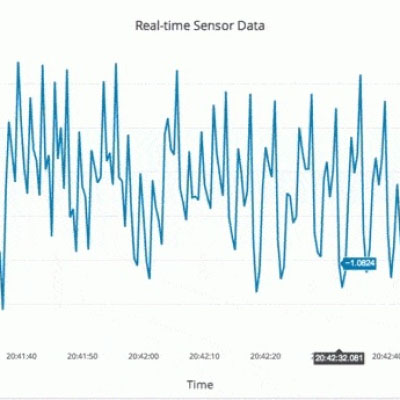

One popular CNC machine tool builder advertises that its customers have read/write access to 6,000 data points. Another boasts that its machinery contains up to 60 embedded sensors, able to monitor everything from the spindle temperature to how much power is being drawn on the axis motors. Like the chatty Cathy in the buffet line, these complex machine tools use a PC-based control spewing thousands of data points from the many different embedded sensors monitoring pressure, and temperature, for different parts of the machine (spindle speed, anyone?). In other words, way too much information for a plant-level operational dashboard.

Since most of that is overkill for what you need to do, we’ll show you only the data you need and spare you the custom development you’d require to get it yourself.What are the benefits of using Mingo for capacity management?

The benefits of using Mingo for capacity management include real-time visibility into production performance, improved decision-making, reduced lead time, and increased efficiency and productivity. Mingo also supports continuous improvement by providing data-driven insights into production processes and employee performance.

Your operators provide meaningful data and insight into your operation. Capture it with Mingo.

When you’re able to view downtime and performance by line, shift, and operator, for instance, machine and sensor data within the right context will provide you deep insights into your overall plant’s performance. To add to this, we also set up and configure manual input from your operators and users into the application. This will allow your people to add data about downtime reasons or quality commentary (e.g., good product vs. bad product). We’re one of the few manufacturing productivity applications offering this, so we can provide you with deep visibility and a more holistic view of the plant floor than you have now.The benefits of using Mingo for capacity management include real-time visibility into production performance, improved decision-making, reduced lead time, and increased efficiency and productivity. Mingo also supports continuous improvement by providing data-driven insights into production processes and employee performance.

Mingo implementation on 10 machines typically takes 3-6 weeks. It starts with an 8-hour site survey, followed by 3 hours of remote training for employees. The biggest variable is connecting to machines, which takes around 40 hours or 5 workdays. Within a month, Mingo can start tracking data and providing value, with 4 hours a week dedicated to answering questions and helping to use the software.