Let’s dive into what waste in manufacturing is REALLY costing you and why you should care…

- The economic side

- The cultural impact

- And what can be done to fix it

Let’s talk money.

In manufacturing, a large amount of waste is produced as a result of the production process. Although some form of waste is inevitable during production do you ever think about just how much waste is accumulated? Could it be reduced? And if so, how will that impact a manufacturer’s bottom line?

To put it into perspective, let’s talk about manufacturing in a global sense. The manufacturing industry is estimated to be worth $40 trillion. That is MORE THAN HALF of the world’s total GDP. If those numbers don’t jump at you enough, let’s put the waste aspect into perspective. “20% of every dollar spent in the industry is wasted – adding up to $8 trillion, or 10% of the global GDP”.

$8 trillion is produced each year in the form of waste. Let that number sink in. That is a lot of waste. Besides the obvious huge economic impact, waste has other effects on a business as well. Waste creates a lot of excess materials and expends time that is… well… a waste. This can cause a domino effect of inadequate organization, planning, and communication if issues surrounding waste are not handled properly.

Now you may be thinking, what do we mean by waste?

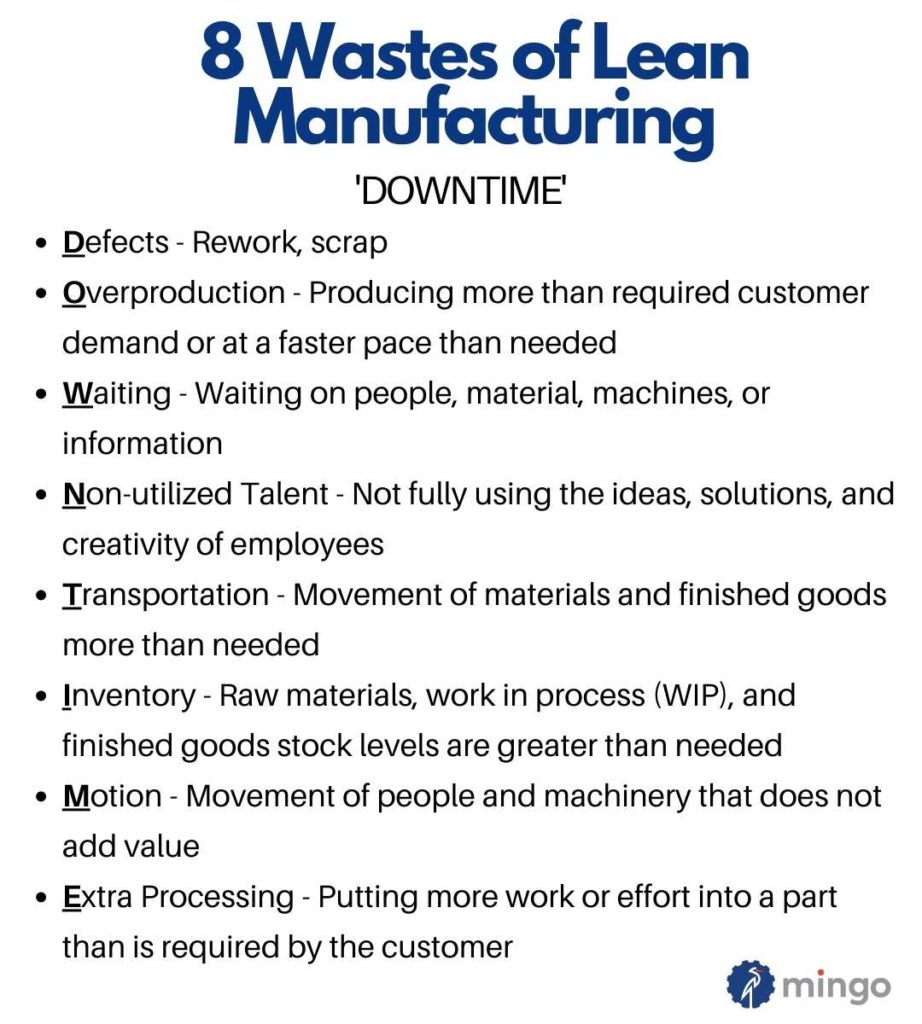

In the world of lean manufacturing, waste is classified as any unnecessary expense or use of the time that does not result in a quality product for the customer. There are 8 different types of wastes with various causes and ways to fix them. Let’s dive into those 8 different wastes…

1. Defects

Producing defective parts ultimately wastes time and materials that could be spent producing a functioning part. Defects also mean time needs to be allotted to make necessary corrections, which can produce unnecessary overtime costs.

Find the root of the defect to reduce defects. The root problem could come from poor machine repair, lack of process standards or proper documentation, inaccurate inventory levels, or a multitude of other things. Finding and fixing the root cause will ultimately ensure that the overall manufacturing process will run smoothly and reduce defects.

2. Excess Processing

Over-processing or incorrect processing results from unneeded steps during production. These unnecessary steps could come from poor tool or product design, lack of communication, or human error. Waste is generated from the over-processing of products and in turn, creates higher-quality products than what is necessary.

3. Overproduction

If you are producing components before they are needed, then you are accumulating waste in many different categories. You are producing waste in the form of physical waste of the materials, while also producing waste in the form of time. Waste in time means that it was not necessary to use the time spent to make that part at that particular time. The overhead costs associated with overproduction include overstaffing costs and storage and transportation costs.

Have a clear understanding of what the customer needs and when they need it to clear up overproduction.

4. Waiting

Waiting can be the result of many different factors. Whether it is waiting for inventory to come in or waiting for maintenance to fix a machine, it is costing you money and time that could be used far more efficiently. Ensuring that processing is going as scheduled can reduce waiting waste.

5. Excess Inventory

If you are producing too much, it could ultimately end up hurting your business. Excess inventory creates a domino effect of damaged goods and high transportation and storage costs. Having an excess of inventory is usually hiding other problems such as production imbalances and defects.

6. Transportation

Unnecessary transportation could consist of moving materials, carrying work in progress over long distances, or any action that results in inefficient transport in the manufacturing process. Poor plant design is a leading cause of transportation waste. Ensure that your plant is designed to create the most efficient transportation of products.

7. Motion

Motion in the context of manufacturing waste means unnecessary movement. This could qualify as any unnecessary motion made by machinery, employees looking for something for an extended time, or walking to complete a manual task that should be automatic. All unnecessary motions result in non-value-added time and increase overhead costs.

8. Non-Utilized Talent

This type of waste is not necessarily process-specific but is arguably one of the most detrimental wastes if ignored. Management has the obligation to make sure that their employees’ talent is being utilized to its full potential. Not utilizing employee talent can lead to lost time, ideas, skills, improvements, and learning opportunities.

Making manufacturing run smoothly is a team effort, so make sure you are listening to everyone on the team!

The “Three M’s”

The Toyota Way categorizes all of these 8 types of waste as Muda, which is a Japanese term that means non-value added. Muda essentially groups the 8 wastes into one category that result in longer lead times, unnecessary movement to get tools or parts, excess inventory, or any type of action that results in waiting.

Diving deeper into the definition of waste, The Toyota Way goes even further by adding two other M terms, muri and mura. Muri is complementary to Muda, as it refers to the overburdening of people or equipment, a form of waste because you’re overutilizing your resources. This means that your employees and machines are being pushed to the max and overworked, which can cause safety hazards, defects, and breakdowns.

Mura refers to unevenness. This results from a fluctuating production schedule or production volume that can result in various internal issues. Downtime, missing parts, and defects result in more hands needed on the equipment and materials in order to stop these issues before mura results in Muda.

These three M’s are all intertwined and essential to understanding the 8 types of wastes that are laid out in The Toyota Way. In order to have a smooth production line, all three M’s must be acknowledged and focused on.

Now that we have taught you what waste means…

All forms of waste in manufacturing stem from poor communication and organization. Lacking communication and organization can break a factory’s process in an instant.

This is why engaging with employees is so essential in the process of reducing waste in manufacturing. By engaging employees and making sure everyone is on the same playing field, organization and communication will need to be cultivated and become seemingly effortless.

We recommend frequent production meetings to promote organization and communication amongst multiple levels of the manufacturing process, inevitably creating an effective company culture.

We have identified waste as a HUGE issue… what is the solution?

Reducing waste has a multitude of benefits for your business as a whole. Materials will be used in the most efficient way, reducing unnecessary costs that were put towards defects. Less will be spent on overtime due to reducing the amount of waste you are producing. And as an added bonus, your employees will be more engaged while hitting their goals with ease. All in all, it is a win-win for everyone from the floor to the C-suite. (This is why it’s important to measure the process, not just the machine.)

You may identify that you have the types of issues caused by waste but are unsure of where to start looking for a solution.

Manufacturing analytics can give you a way to solve your waste problem by promoting organization at multiple levels of the manufacturing process. Everything from making sure processes are running smoothly, reducing downtime, to customization features that mold to your needs – manufacturing analytics has your back.

References:

Forbes: Manufacturing Wastes 10% Of The GWP Every Year. Here’s Why.