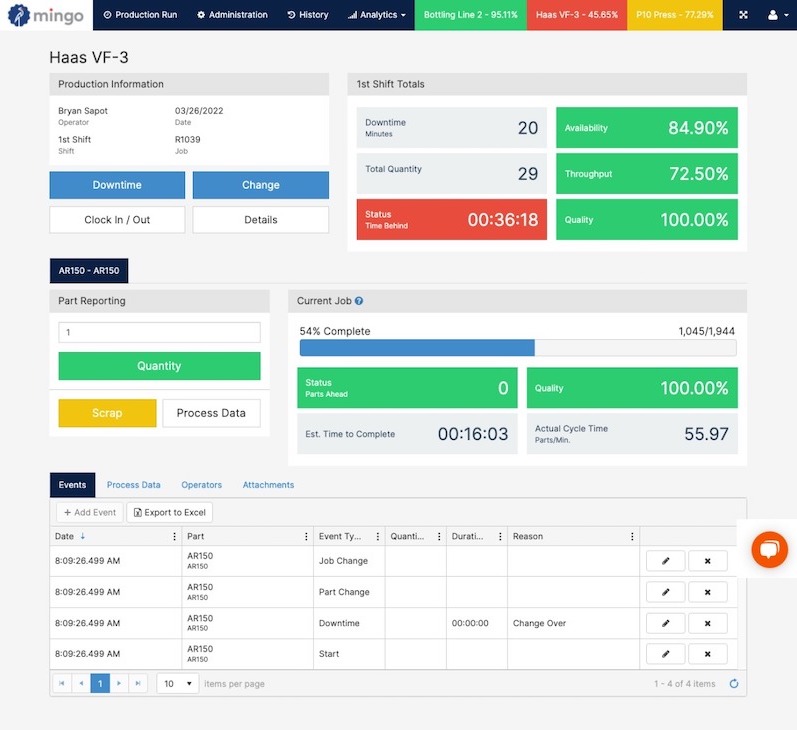

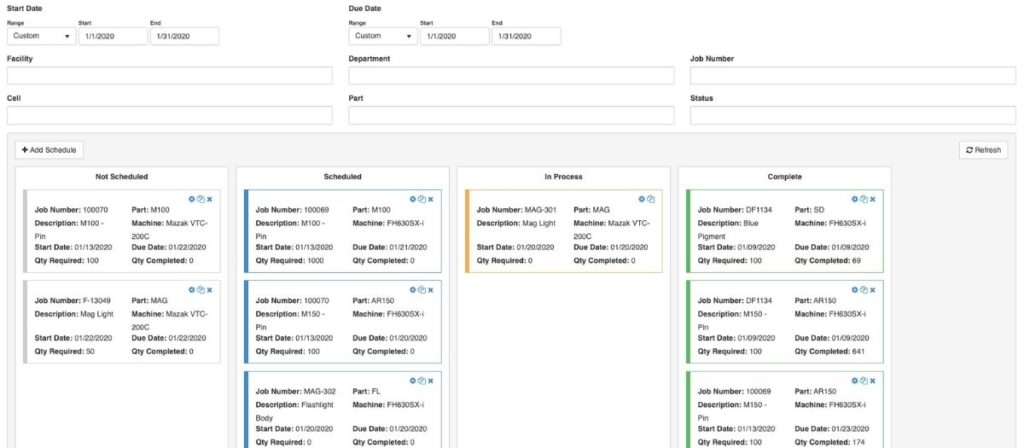

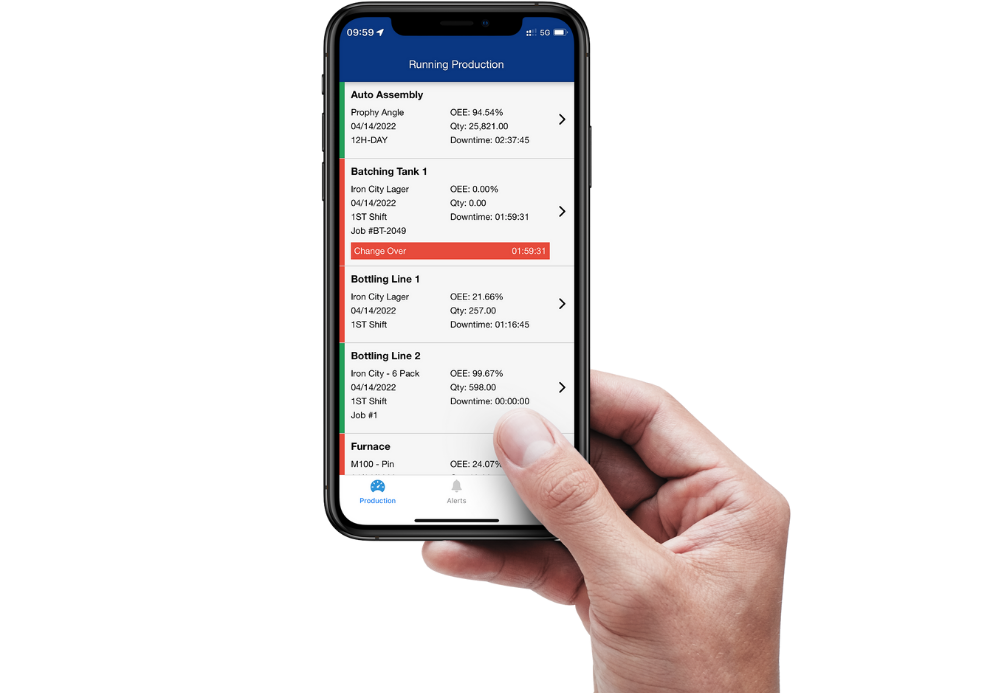

At the end of the day, you need visibility into what’s happening in the plant. You need to get control of your schedule, reduce unplanned downtime and overtime, focus on your continuous improvement efforts, ensure quality, eliminate manual reporting, improve margins, increase efficiencies, and know what’s happening in real-time. It may sound impossible and overwhelming, but with the right manufacturing productivity software, it becomes possible (and much less daunting).

As you know, choosing the right solution is no easy feat. You have to make sure it’s going to help you achieve your goals. So, how and where do you start the selection process?

First and foremost, you need to outline your goals and what you’d like to achieve with a manufacturing productivity solution. Then, do your due diligence. Set up custom demos, talk to the sales teams, read reviews from sites like Capterra and SoftwareAdvice, see what companies are writing about via blogs, and learn from other manufacturers who use the software solutions. There’s so much research you can do prior to choosing software for the plant. When you’ve done this, you’ll be much more equipped to decide which software, Mingo vs. Worximity, is going to be the better solution for your needs.